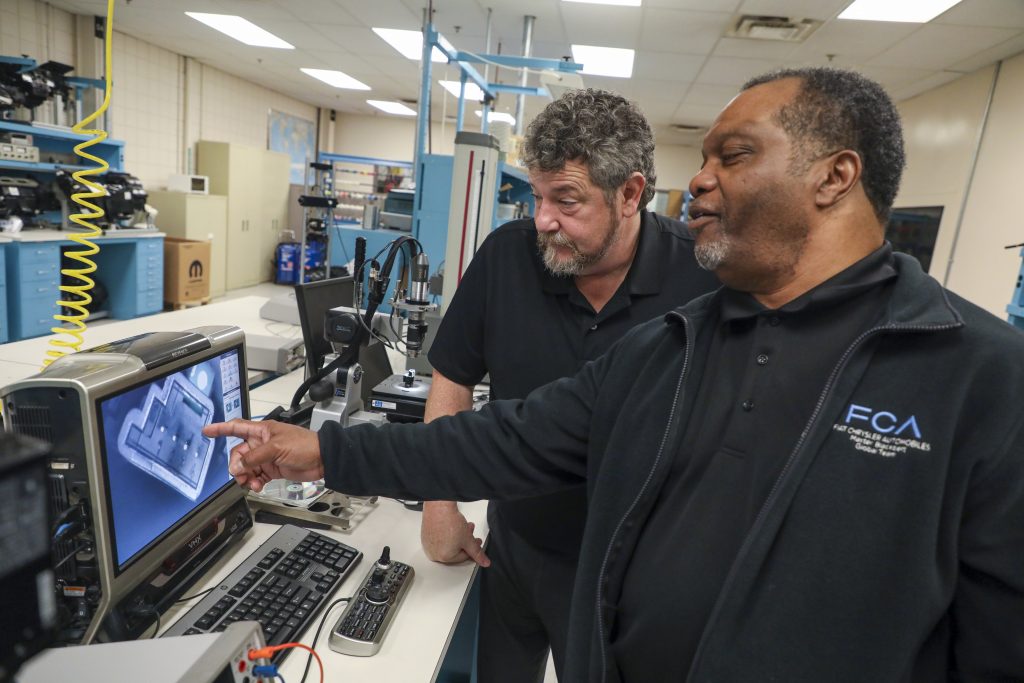

When Victor Gaylor walks into an assembly plant, he is judge and jury.

He looks and listens and, if he finds evidence linking a vehicle component to a customer concern, he holds court. “We put it on trial to see if it’s guilty,” says the veteran FCA quality auditor.

This no-nonsense, product improvement approach recently won FCA a docket full of favorable verdicts from a pair of third-party quality watchers.

“We’re not holding anything back,” says Mark Champine, Head of Quality, FCA – North America. “Every day, we are striving to deliver a superior ownership experience for our customers.”

Gaylor, who has been with the Company since 1998, is one of two FCA employees to take home an RT5 Leadership Award from Shainin, a global engineering service company specializing in root-cause investigation and professional development.

He earned the prize by spearheading a project that reduced cabin noise by 24% in the popular Dodge Durango SUV and in its legendary line-mate from FCA’s Jefferson North Assembly Plant, the award-winning Jeep® Grand Cherokee.

“I am probably more critical than anyone,” Gaylor says. “I like a quiet cabin and I think our customers deserve a quiet cabin.”

But his project didn’t end with the product. A colleague “decided I could take it a step further,” he adds.

That colleague was Jud Estes, a quality engineer and “Master Black Belt Instructor” – the highest of four certifications awarded through the industry-standard Six Sigma quality improvement process.

Estes challenged Gaylor not only with reducing cabin noise, but with training his team members to achieve “Black Belt” problem-solver status. Through similar initiatives spanning four decades of refining everything from seat cushions to Formula One pistons, Estes estimates he has helped increase the world’s population of Black Belts by 10,000.

But Estes doesn’t just go by the book when it comes to quality improvement processes. He goes by several books, from Shainin and Six Sigma, to Kepner-Tregoe.

“The assembly of these tools into the FCA system is unique,” Estes says, himself the winner of the 2019 Shainin Medal, presented by the American Society for Quality (ASQ).

The honor stems from his development of “Reverse Group Comparison,” which deconstructs a system – component by component – and measures the incremental benefits of each.

Estes says it seeks to answer the question: “What are the ingredients I could put into the recipe to make it better?”

Joining Gaylor as a 2019 RT5 Leadership Award winner is Rodrigo Espinoza, who led a training and certification initiative for FCA in Mexico. FCA’s body engineering group earned Shainin’s Bottom Line Improvement Excellence Award for its work on enhanced headlamp performance.

That team effort helped the 2020 Ram 1500 become the first pickup truck to earn a rating of Top Safety Pick+ from the Insurance Institute for Highway Safety.

“FCA is known for outstanding, innovative design,” Champine says. “We want to do justice to our vehicle designs through greater discipline in engineering and manufacturing. When we do that, our customers win.”